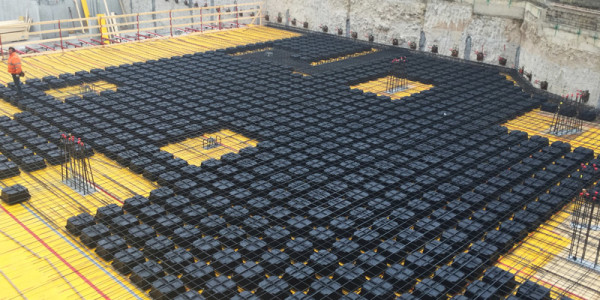

Paul Biya Stadium (even known as Olembe Stadium) is a sport facility in Yaoundé, in Cameroon, for whose construction, some innovative materials and solutions, such as Iglu’® by Daliform Group, were chosen.

With its 60,000 seats, Paul Biya Stadium aims to become the new landmark of the Cameroonian capital.

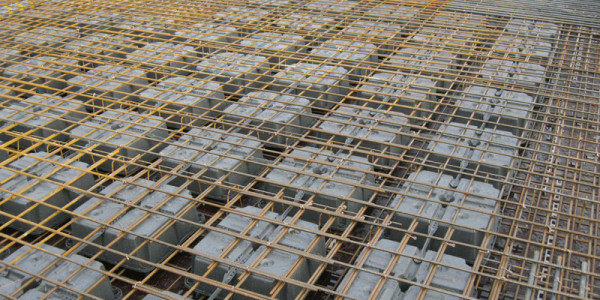

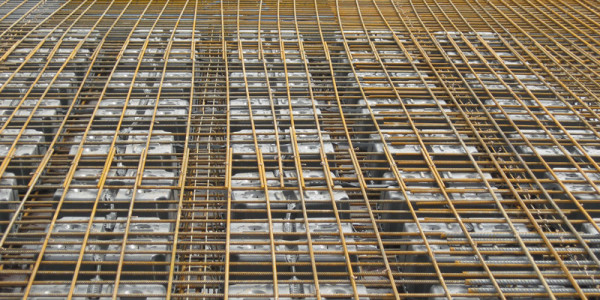

Iglu’® was chosen and used to create ramps, steps, structural fillings and height compensations.

The quality of the used recycled material, its particular geometric conformation, the thickness, the product’s dimension and the processing techniques make Iglu’®, by Daliform Group, the excellence product on the worldwide market.

Numerous national and international awards have been received over the years which testify to the rich and appreciated contribution that Iglu’® has managed to give to the world of construction.