U-BOOT® BETON IS A RECYCLED PLASTIC PERMANENT FORMWORK FOR VOIDED BIAXIAL SLABS.

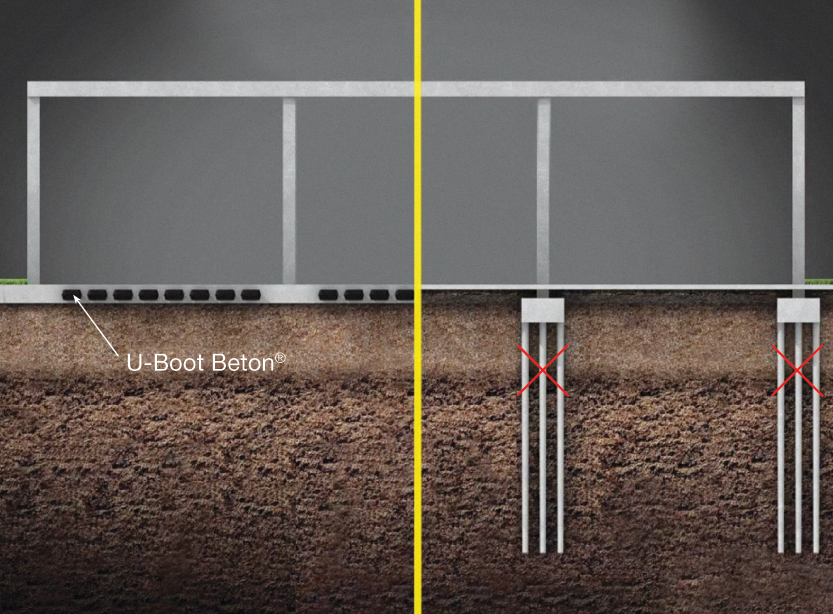

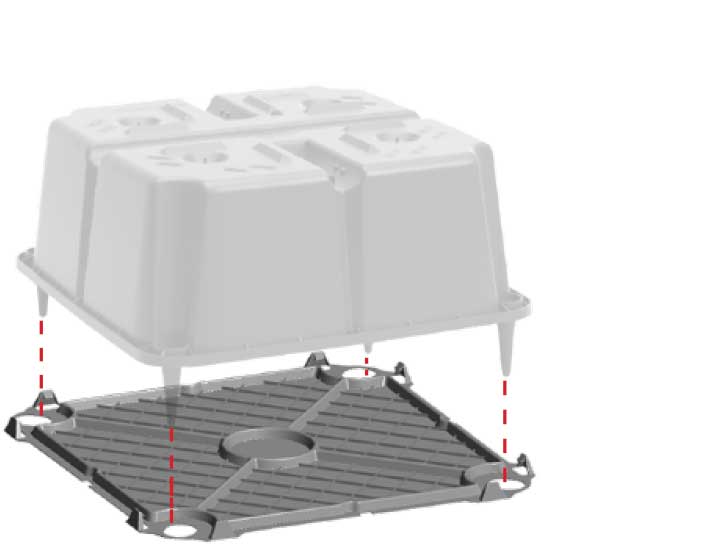

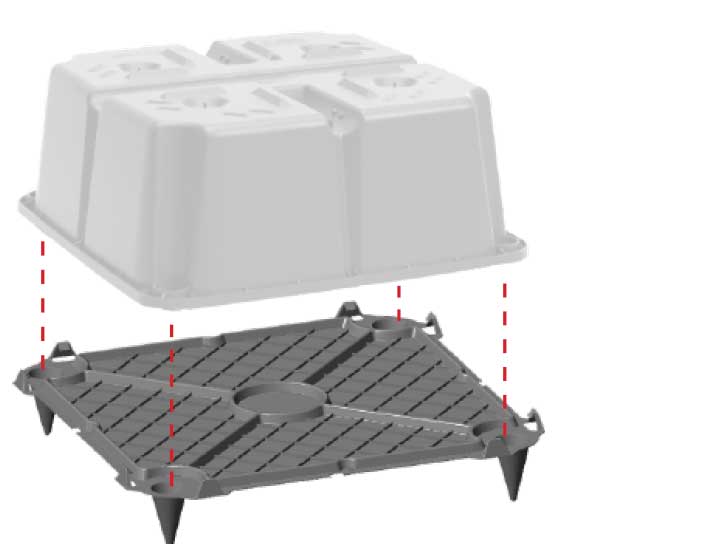

The patented U-Boot® Beton allows to build lightweight structural concrete slabs and rafts, by creating internal voids placed in zones where the shear demand is low.

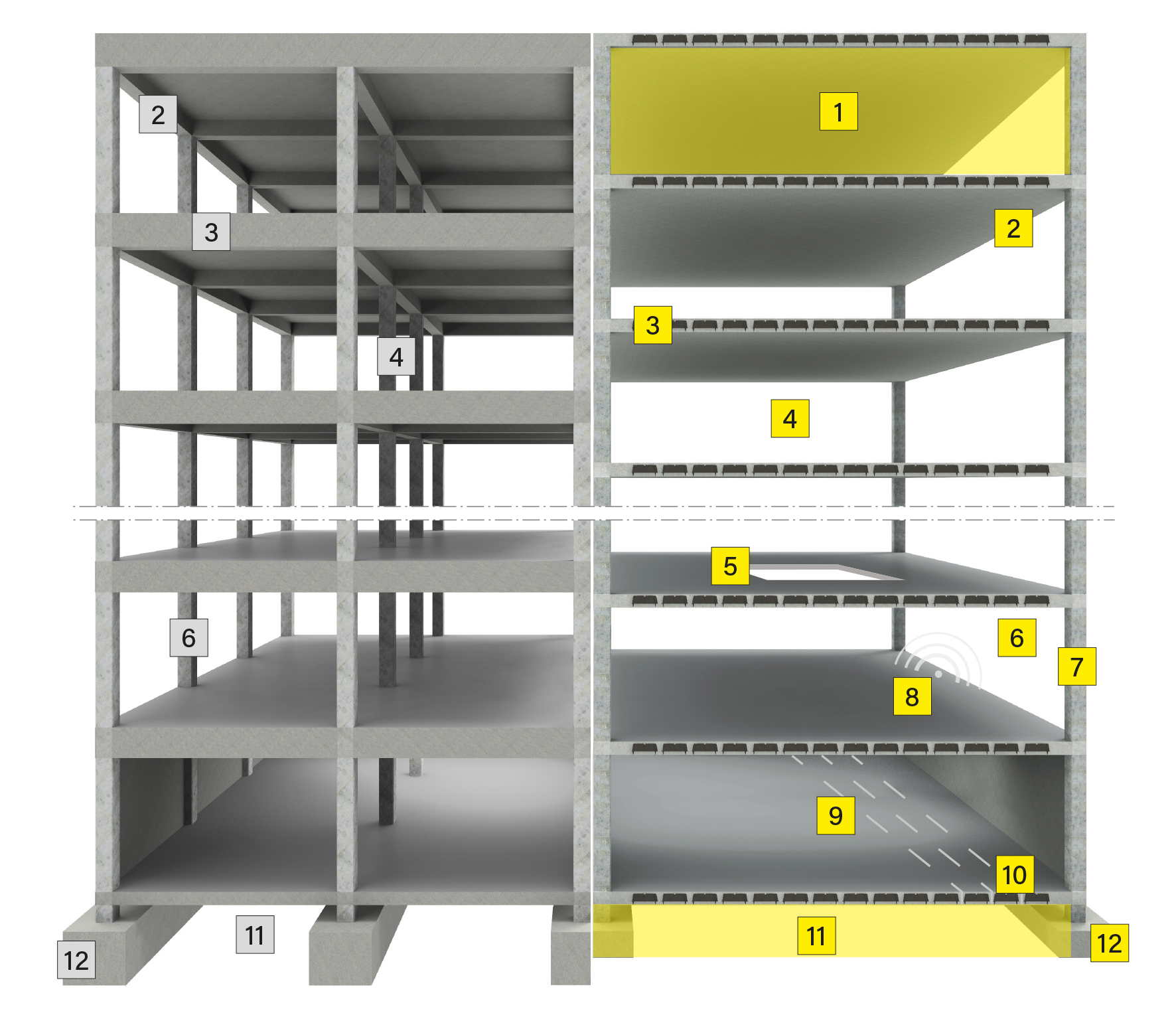

This technology is the ideal solution for creating slabs with large spans and great load-bearing capacity, which allow designers to be more creative and free in the use of space, as the slabs are thinner, totally flat and may require a slimmer supporting structure, without the need of ribs and drop panels around the columns. This is achieved by embedding the U-Boot® Beton formwork in the concrete, resulting in the formation of a hollow core plate, with continuous lower and upper slabs, connected by orthogonal ribs, interconnected with each other.

The U-Boot® Beton voided flat slabs offer an efficient and sustainable solution to architects, engineers and contractors, thanks to the reduction of concrete and steel in the slabs, columns and foundations, as well as the reduction of the embodied carbon of the entire building, compared to a conventional concrete structure.

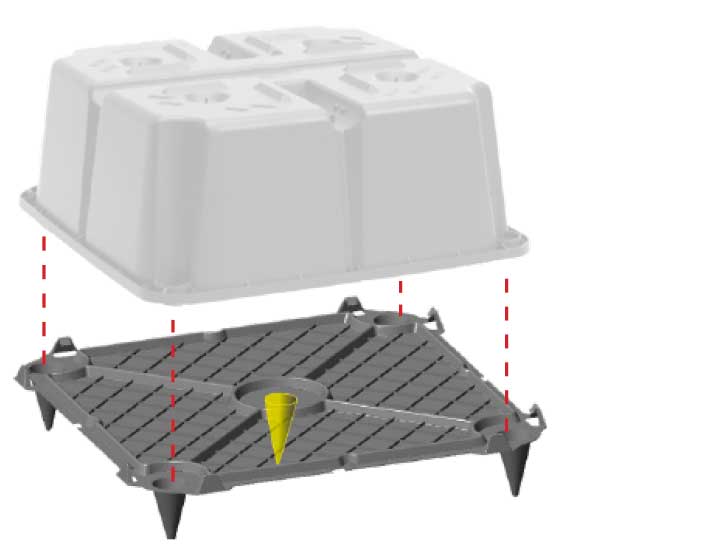

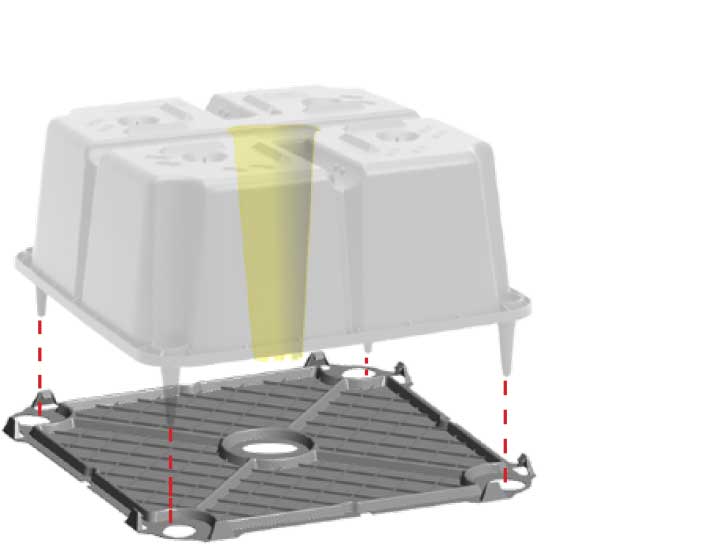

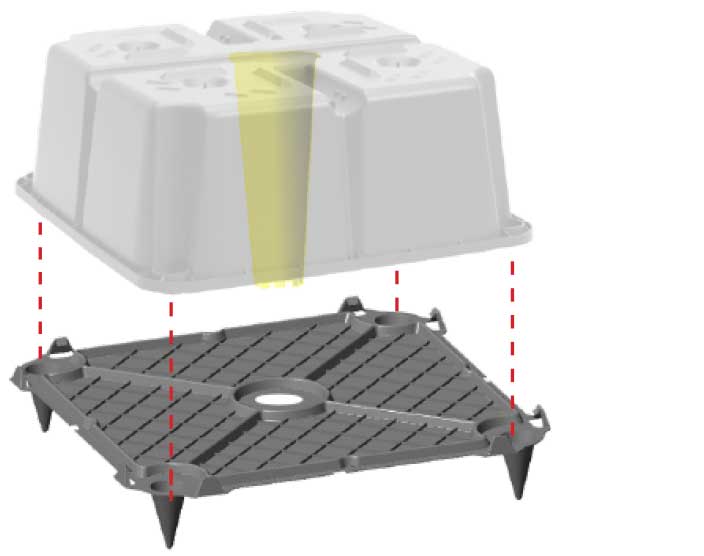

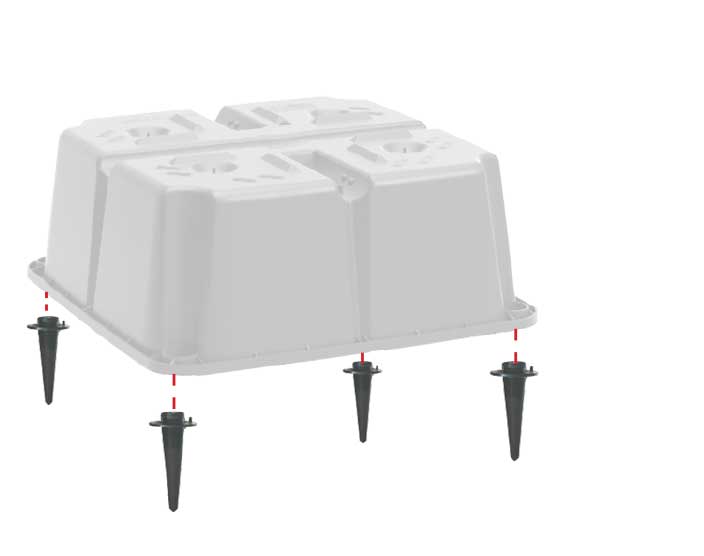

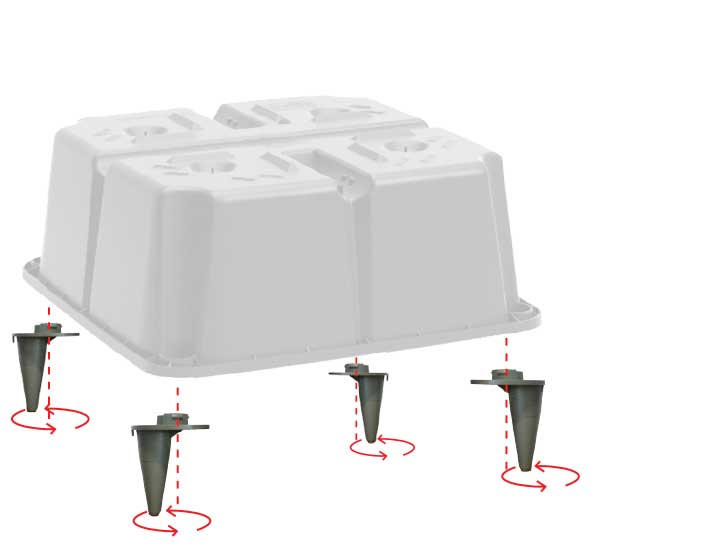

Due to its modularity, simple handling and toughness, U-Boot® Beton reduces construction times and associated costs, and improves the technical performance of buildings.