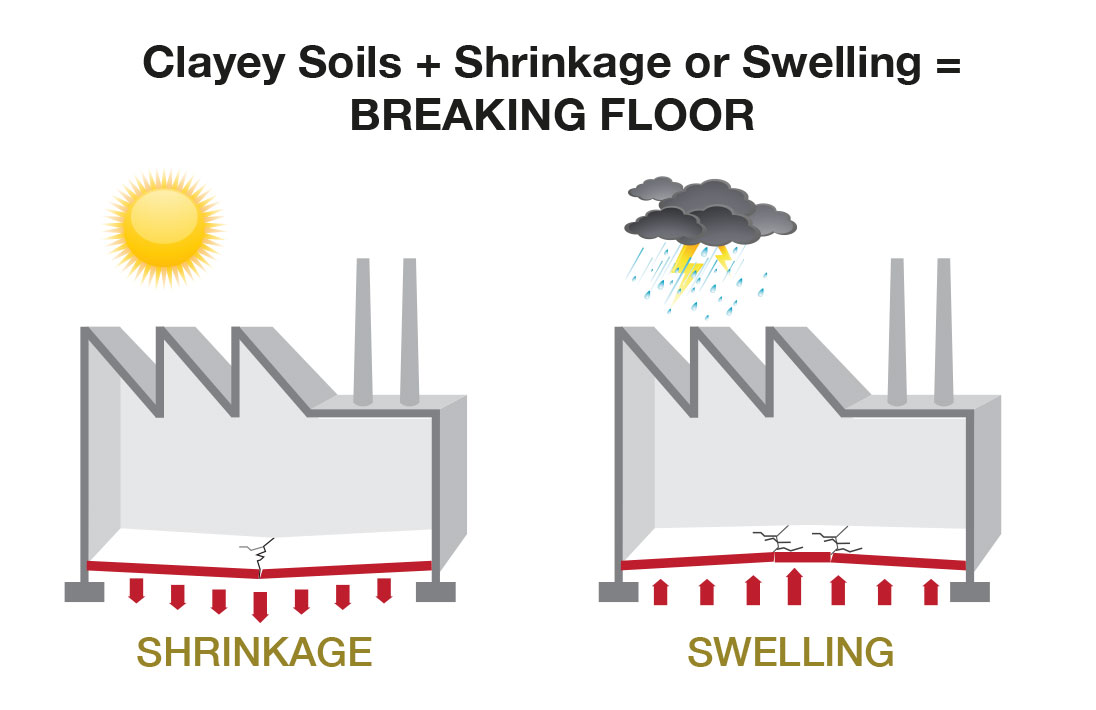

With foundation problems in clayey soils, conditions which facilitate a “proactive” approach with regard the soil rarely occur within the scope of the project.

In most cases, the structure is designed and its behaviour is then anticipated as a function of the mechanical characteristics of the soil, while only seldom is it possible to act on these in order to modify unfavourable environmental conditions.

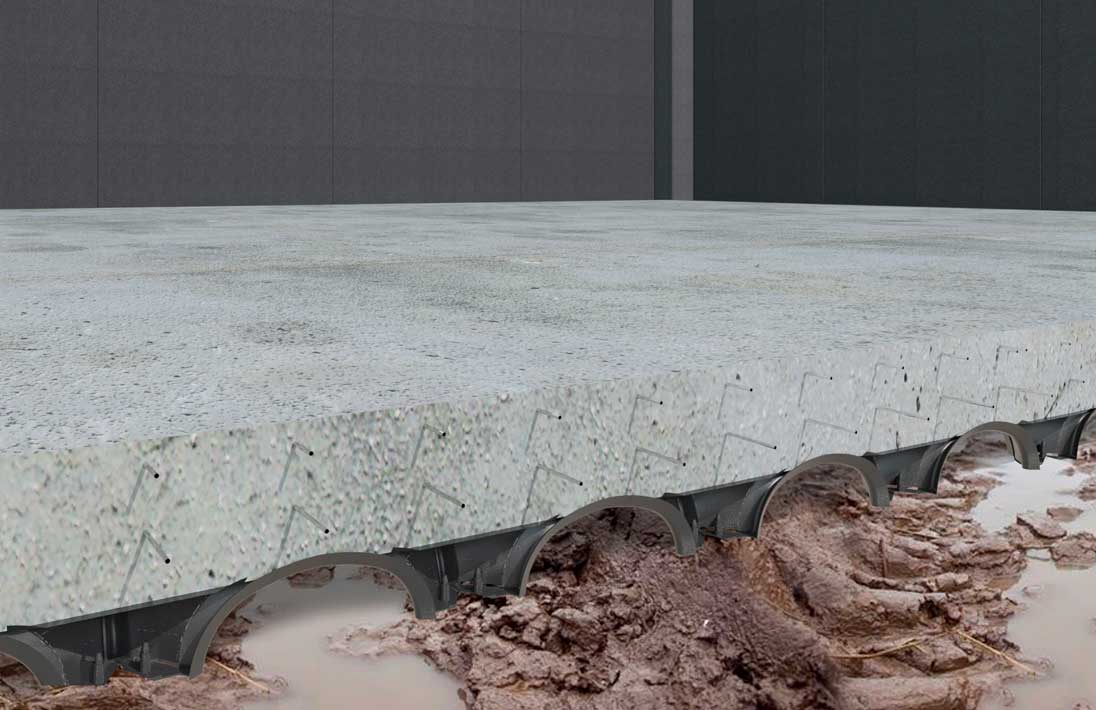

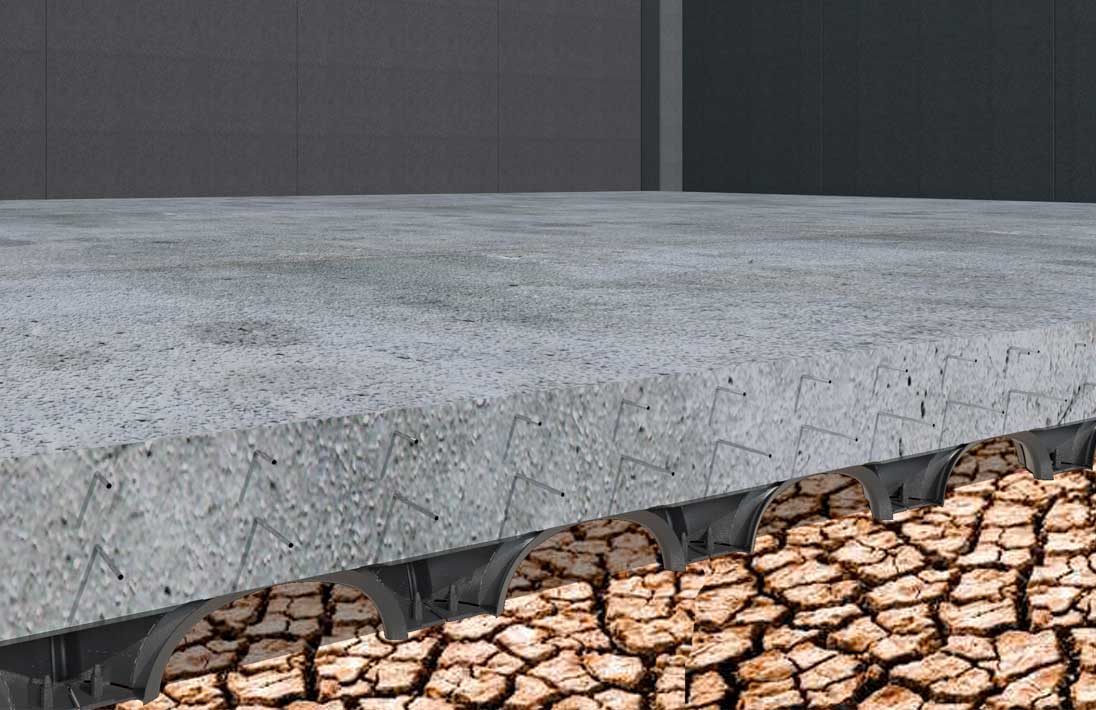

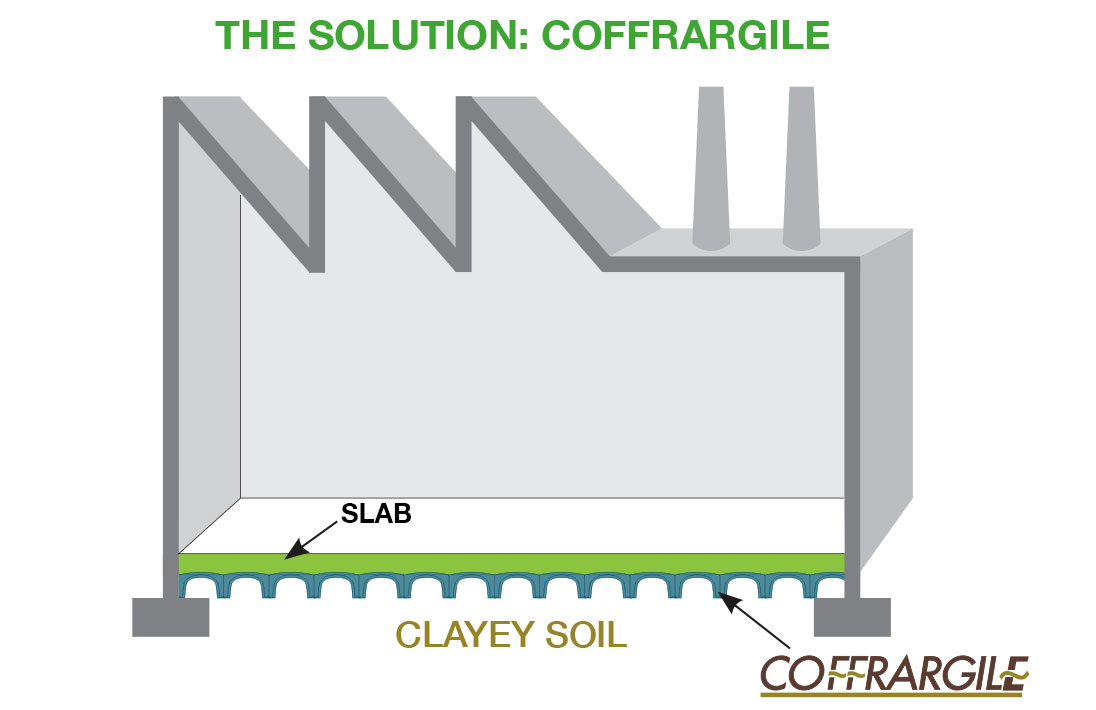

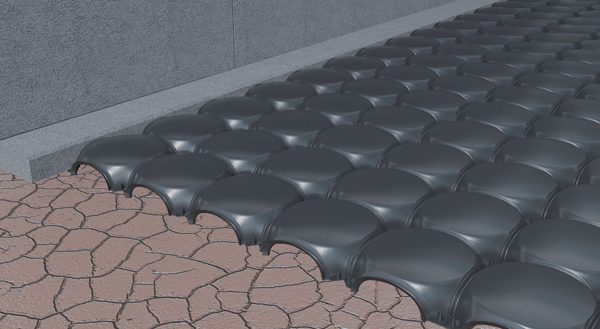

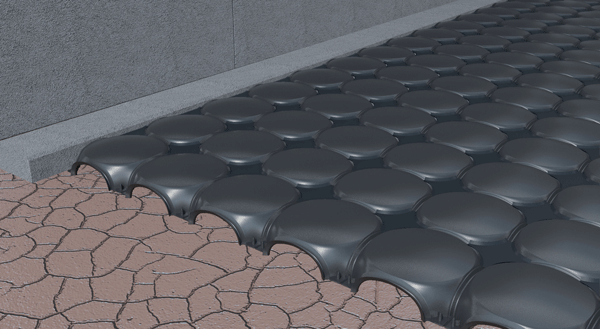

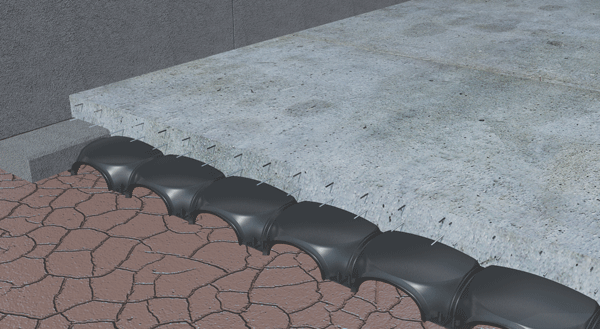

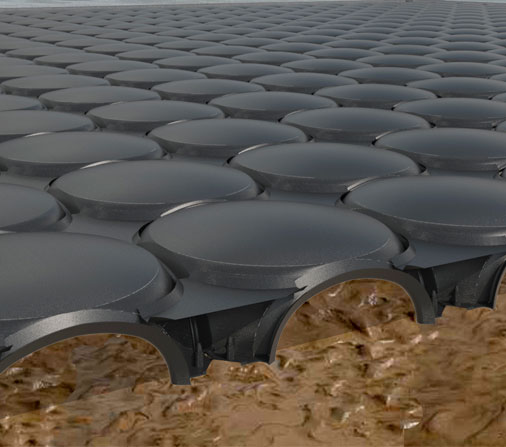

Daliform Group created Coffrargile, a disposable formwork made of recycled plastic, to effectively handle the movements of clayey soils and protect floors from shrinkage/swelling.

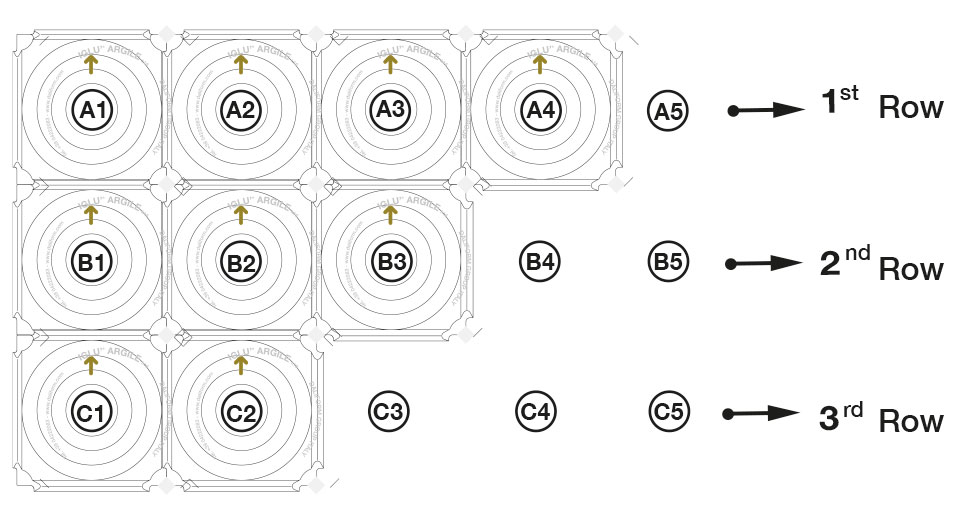

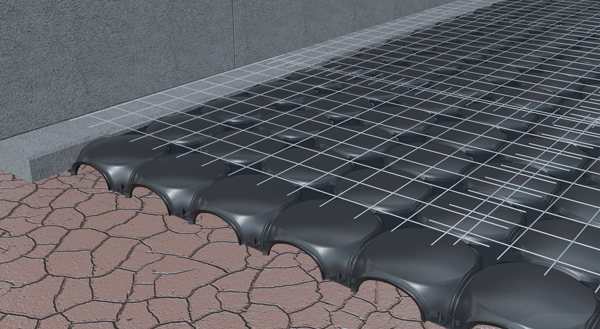

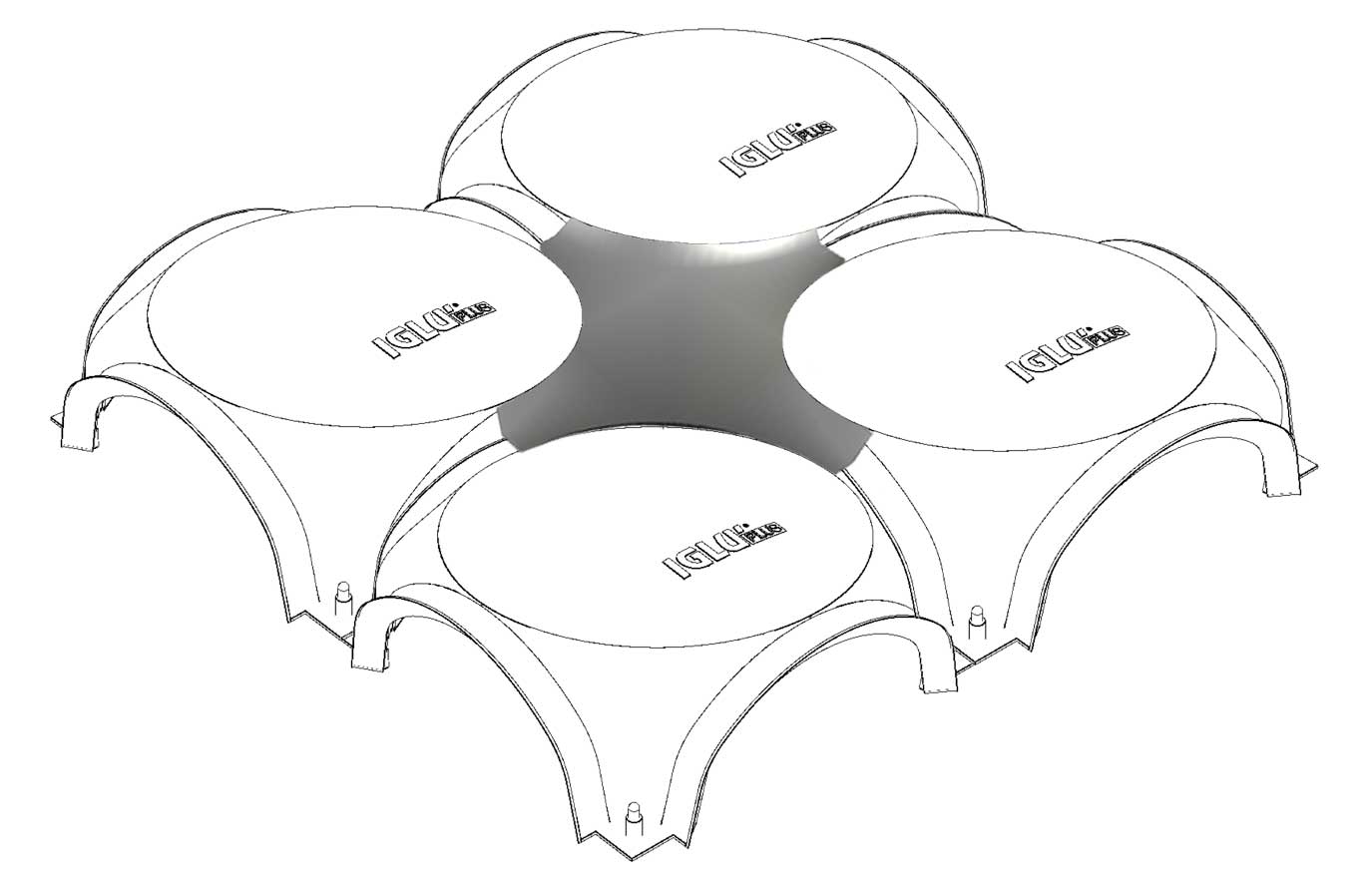

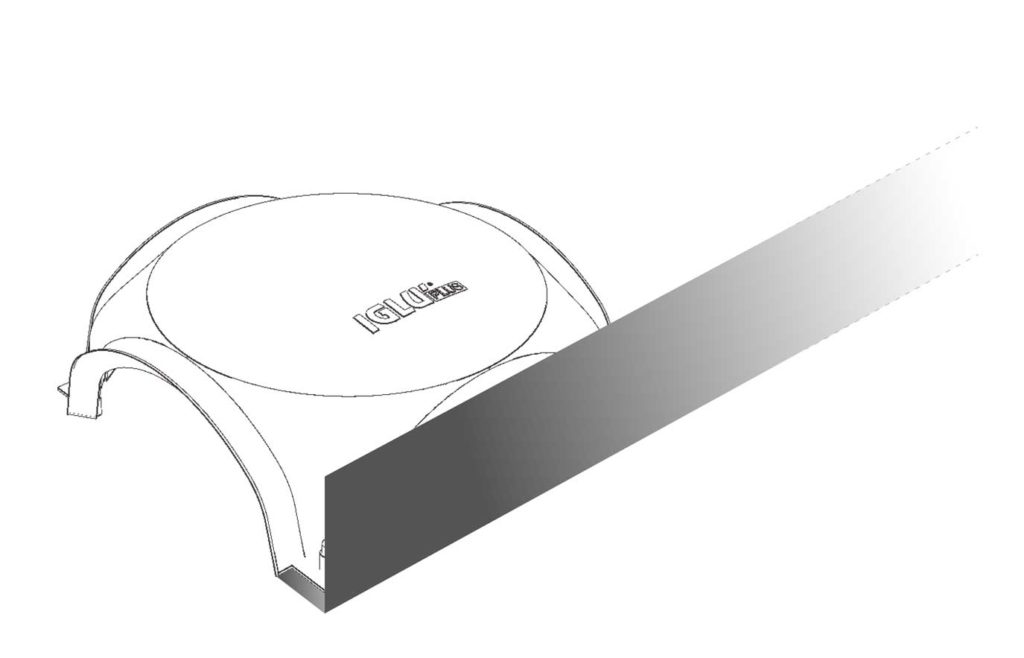

Coffrargile is used in combination with Beton Up, an accessory that prevents the reinforced concrete from forming the “pillars” typical of the classic Iglu’® system.

In this way, the formworks take on the function of simple scaffolding on which a load-bearing slab of reinforced concrete can be installed with a cavity below, the purpose of which is to accommodate the swelling and shrinkage of the sediment underlying the foundation due to the special mechanical properties of clayey soils.