Urban regeneration is a crucial component in the sustainable development of contemporary cities. Through targeted interventions, disused and degraded areas can be transformed into vibrant and functional spaces, meeting the needs of an ever-evolving society. An exemplary case of such transformation is the renovation of the former fruit and vegetable market in Genoa.

Urban regeneration extends beyond mere building restoration; it encompasses the redevelopment of entire neighbourhoods, enhancing the quality of life for residents, promoting environmental sustainability, and stimulating the local economy. This process may include the rehabilitation of historic buildings, the creation of new public spaces, the improvement of infrastructure, and the promotion of sustainable mobility. One of the most effective approaches in urban regeneration is public-private collaboration, which combines resources and expertise to realise ambitious and impactful projects.

The Redevelopment of the Former Fruit and Vegetable Market in Genoa

The former fruit and vegetable market in Genoa serves as an ideal case study for understanding the significance of urban regeneration. Situated in a strategic location within the city, this space had languished in neglect for several years, becoming a symbol of decay. Thanks to an ambitious redevelopment and reuse project, the area has undergone a radical transformation, emerging as a hub of attraction that fosters greater social cohesion. The design of this new multifunctional space has preserved the historical memory of the complex, creating a large park for the community and commercial spaces for local businesses.

U-Boot® Beton: Technology at the Service of Regeneration

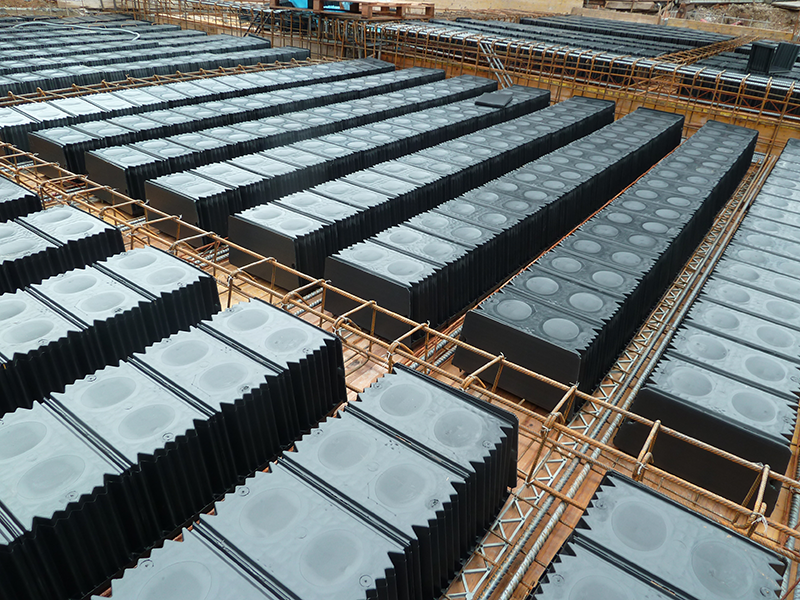

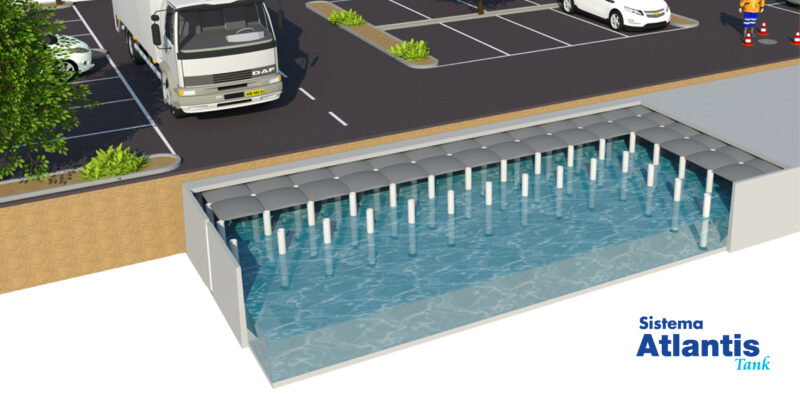

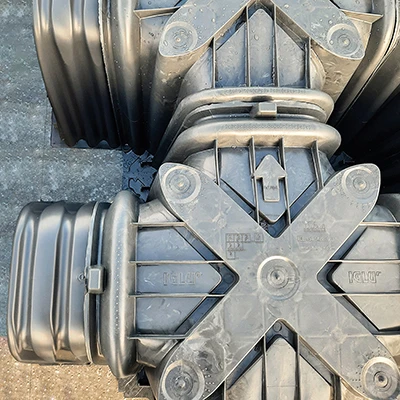

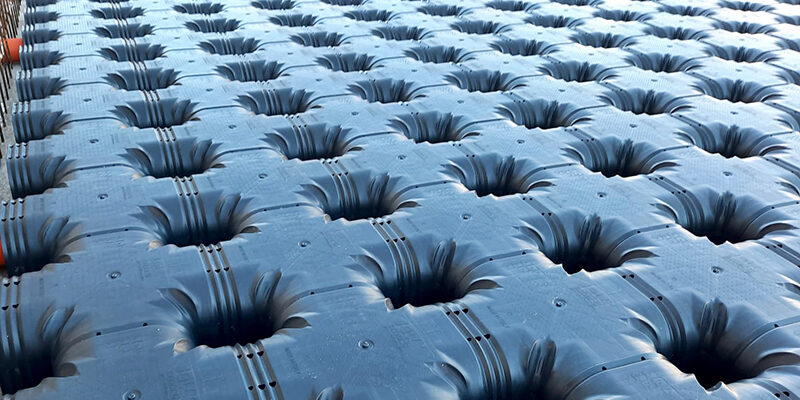

A distinctive feature of this project was the utilisation of U-Boot® Beton, a recycled plastic formwork for voided biaxial slabs, offering several advantages:

- Reduction in Structural Weight: By unburdening the floor, it was possible to reduce the load on the bearing structures, facilitating renovation without compromising stability.

- Environmental Sustainability: U-Boot® Beton contributed to reducing the environmental impact of the project, thanks to the significant savings in concrete and steel.

- Design Flexibility: The versatility of U-Boot® Beton allowed for easy adaptation to specific project requirements, as it is ideal for buildings with complex geometries.

Urban regeneration is a complex yet indispensable process to reintegrate disused or abandoned areas into our cities. Investing in urban regeneration means building a better future for the community, transforming forgotten spaces into places of opportunity and growth.